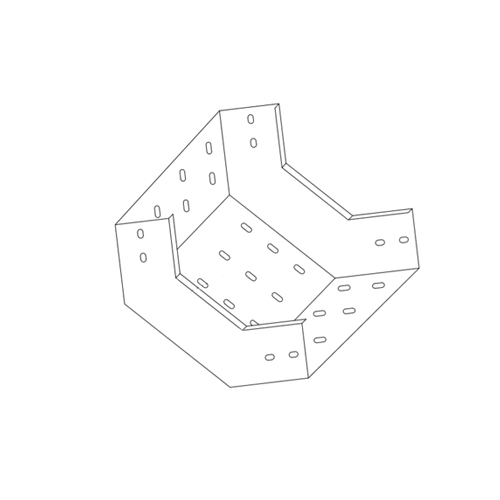

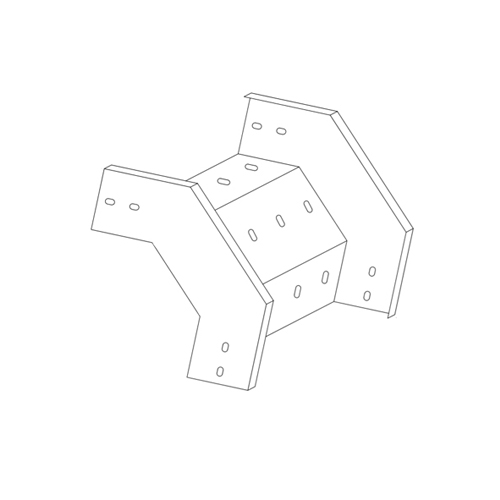

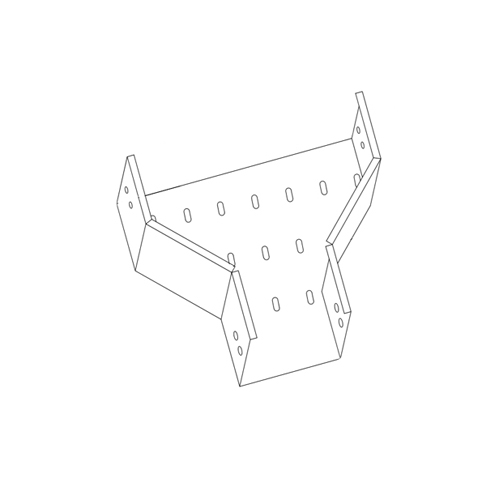

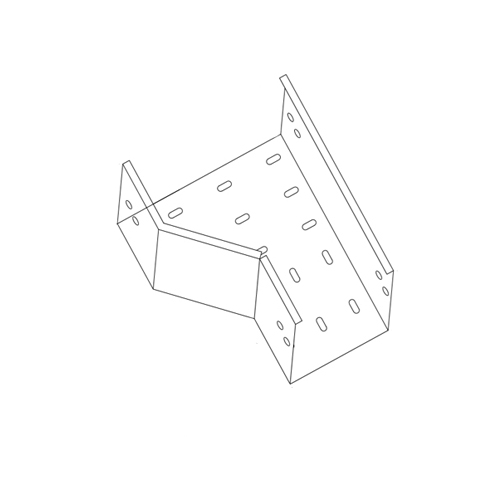

Cable tray

Specicfications

| Standard | NEMA VE 1 - 2002 | ||||||

| Width (W) | 50, 75, 100mm – 1000mm | ||||||

| Height (H) | 50mm, 75mm, 100mm, 150mm, 200mm | ||||||

| Thickness (T) | 1.0mm, 1,2mm, 1.5mm, 2.0mm Hot dipped galvanized: T (1.5~2.0mm) |

||||||

| Length (L) | 2500mm | ||||||

| Finished surface (F) | Electro powder coating(E), Pre-Galvanised(G), Hot Dip galvanised(H) |

||||||

| Standard colors |

Gray RAL 7035 / Orange RAL2004 / Blue RAL 5005. Other colors can be supplied according to customer requirements |

||||||

| Lưu ý | W >= H |

Product information

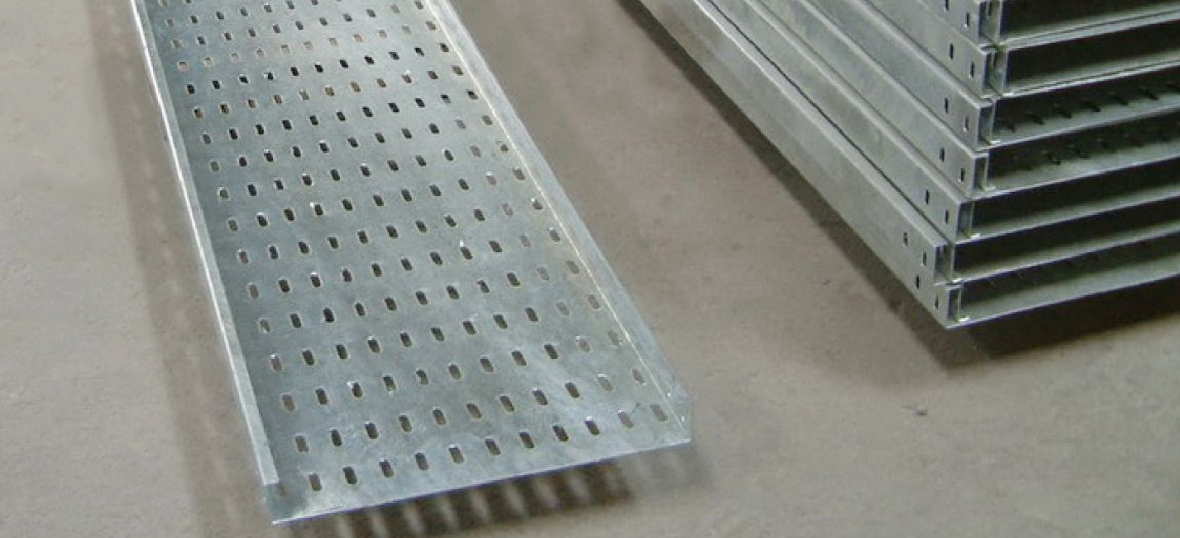

Cable tray (also called the tray tray) is a tray that supports and installs electrical cables and cables (with insulated covers), used for installing wires and cables in factories, apartments, building...

Specifications

- Materials: Black corrugated iron, corrugated iron and steel sheets.

- Finished surface: Electro powder coating(E), Pre-Galvanised(G), Hot Dip galvanised(H)

- Standard thickness: 1.0mm - 2.0mm

- Standard width: 50mm ÷ 1000mm

- Standard height: 50mm ÷ 200mm

- Standard length: 2500mm

- Standard paint colors: RAL 7032, 7035. Other colors can be supplied upon customer's request.

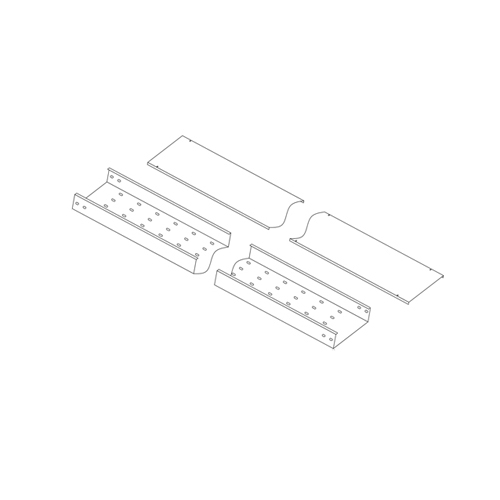

- Cable ladders usually do not have lids. If any must be further requested.

Advantages of cable tray

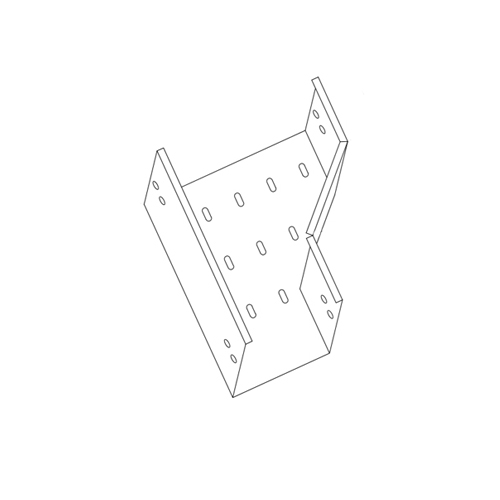

Advantages of the cable tray cable tray design is basically the same as the cable tray, but the body of the cable tray is perforated with the same dimensions, depending on the design, there are different types and shapes of the cable tray. The punching on the cable tray is made by specialized CNC machine to ensure aesthetics and high accuracy, the finished cable tray always meets the technical and quality standards.

Cable trays are used to guide cables and wires to save work space, protect cables and ensure safety for users. Cable trays create higher ventilation and ventilation for the conductors. The holes in the cable tray will help the inner lines not overheating, or overheating during the hot season or during operation. Perforated cable tray is a very effective solution for natural wiring and ventilation.

Disadvantages of cable tray

Cable tray has a natural ventilation mechanism, in contrast to the ability to protect electrical wires and cables completely from dirt is very limited, the dirt in the air can follow the holes to attach to the line. So with wiring in a dusty environment, users should not use perforated cable tray. However, for indoor installations, in the workshop customers can consider using perforated cable tray to wire.

_-24-10-2019-14-59-18.png) NAM HOA ME JSC

NAM HOA ME JSC